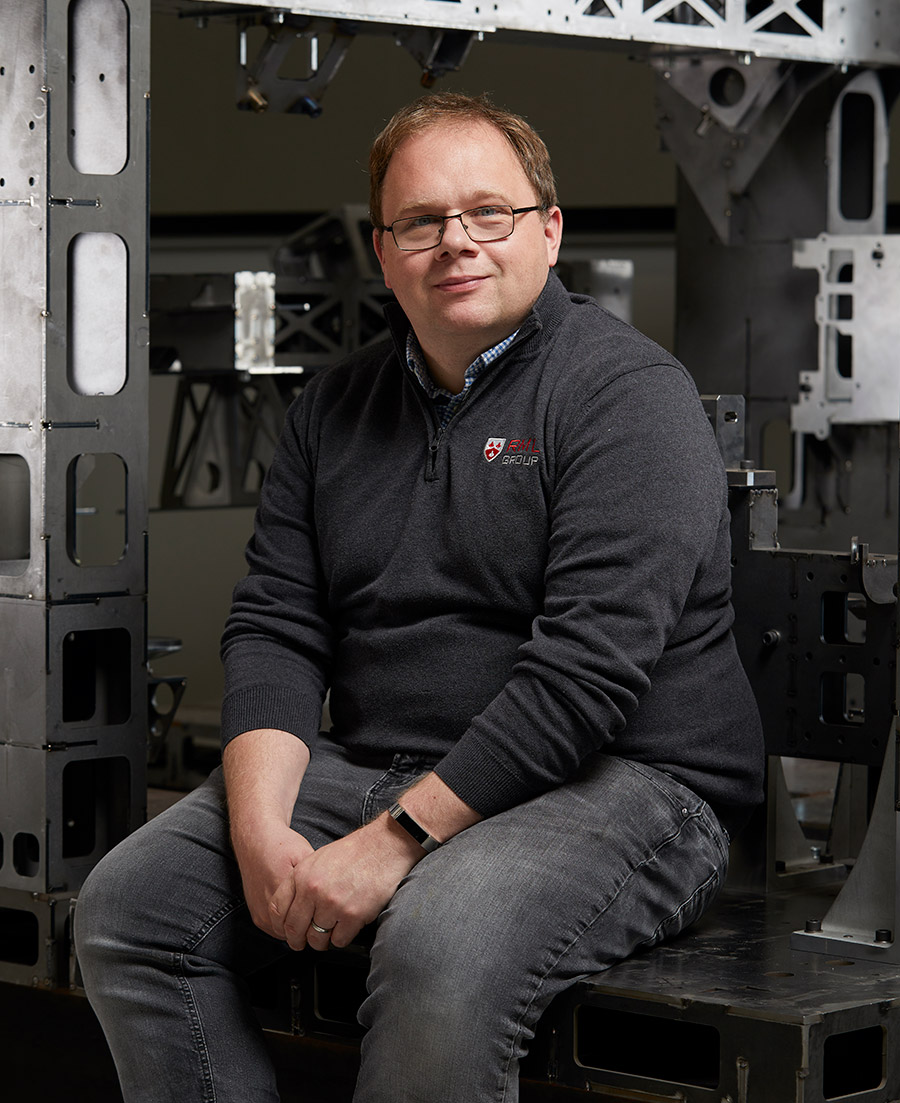

Nic Rutherford is a busy man these days. As Project Lead Engineer for RML’s upcoming Short Wheelbase model – set to be one of this year’s most memorable re-imagined classic GT cars – it’s his responsibility to bring together all the elements that have been painstakingly developed for the car over the last two years, and productionise them.

‘Attention to detail’ has been the development team’s mantra from day one, and nothing illustrates that better than the exhaustive process in constructing the Short Wheelbase’s chassis and body in white. “There are three areas we focus on,” say Nic. “The all-new components used in the chassis; detailed refurbishment of any carry-over sections; and then modification of certain components which are carried over from the Ferrari 550’s platform. What has helped us achieve such a high standard throughout this process is scanning every component and then reverse-engineering them so they integrate perfectly with the new design of the Short Wheelbase.”

With the Short Wheelbase’s body-in-white jig now complete (see pic), new parts are laser cut and scanned to minimise any deviation from specification. The jig allows for a maximum 0.25mm tolerance – an exceptionally low figure – and guarantees that the fit and finish of each car’s chassis/body meets the same standards buyers would expect from a premium manufacturer producing thousands of cars.

“And of course, this is something we’re used to doing,” says Nic. “RML already has vast experience in developing and producing high-end vehicles for well-known OEMs. It’s just that this time, the car has our name on it.”

Before the Short Wheelbase’s carbon-composite body is fitted, the 550’s central chassis section is aligned with the suspension mounts on the jig to make sure that it sits correctly. The newly formed sections are then added, along with the seat and body mounts, before everything is finally welded and sent to be e-coated (an electrophoretic application) and powder-coated.

Reinforcing the drive for exacting quality standards is the Short Wheelbase’s main body section. which is formed as one complete part, from windscreen to tail. This not only minimises the risk of tolerance deviation, but also creates an immensely safe and rigid structure in the event of an accident. When the main and front sections are fitted to the chassis, the structural build is complete and sub-assemblies like the V12 powertrain, bespoke interior and modified suspension can be added.

“After two years of development, the 60-strong team from RML dedicated to the Short Wheelbase is on the brink of productionising a truly unique car that embodies everything that our company does so well. We’ve talked a lot about the Short Wheelbase combining classic form and contemporary function, but what will also set this car apart is the team’s uncompromising attention to detail throughout the production run.” – CEO, Michael Mallock

Each car from the proposed run of 30 Short Wheelbases will take around six months to complete, with the capability of up to six builds in process at any one time to meet the already strong demand from across the world.

Production of the first Short Wheelbase will start before the end of this year, with initial customer cars being delivered in early 2022.