Modern day supercars arguably owe a debt to Lamborghini for automotive audacity. A disgruntled Ferrucio Lamborghini found no satisfaction from Enzo Ferrari over problem clutches. Lamborghini knew tractors and set about making cars of his own in 1963, setting the stage for a rivalry that continues today. For automotive enthusiast, a pilgrimage to Lamborghini can turn a poster on the wall into something much more tangible. The Speed Journal recently made the trek and enjoyed a tour of the museum and assembly line.

Ground breaking designs from Bertone and designer Marcello Gandini made Lamborghini a global name and a synonym for anything fast and exotic. The Miura and Countach are decades old, but still inspire and turn heads. Few others have been able to top Lamborghini for outrageous shapes and colors.

The Lamborghini company itself has seen drama, with ownership changes and ebbs and flows between success and challenges. Through it all, Lamborghini has maintained its headquarters and factory in the Italian town of Sant’Agata Bolognese which is near the city of Bologna and part of the Emilia-Romagna region. The region is often known as Motor Valley and is Italy’s racing and automotive heartland. Lamborghini joins familiar names such as Dallara, Ferrari, Maserati, Ducati, Pagani and dozens of specialty suppliers in calling this region home.

About 2,000 people work at the Lamborghini factory. The cluster of factory buildings and residential neighborhoods is surrounded by wide open, flat farmland. Farm machinery mixes with brand new Lamborghinis clad in protective covering that just emerged from the assembly line. All Lamborghinis get a test drive before delivery.

The museum is filled with highlights of Lamborghini history. A timeline on the wall highlights corporate milestones in words to accompany the displays. Sleek white floors with glass and metal let the automobiles be the stars.

Lamborghini rightly celebrates its past. Early cars like the Espada, Miura and Uracco educate those who are not familiar with older models and excite those who are. Not only do Lamborghinis display the raging bull badge, Lamborghini names are drawn from the bull fighting tradition.

Founder Ferrucio Lamborghini was born under the zodiac sign of Taurus. The Espada is named after the sword that a matador would carry. The Uracco means “small bull.” The Miura was named after a particular breeder of Spanish fighting bulls and was the first Lamborghini to carry a bull-inspired name. When fully opened, the doors of the Miura look like upturned bull horns.

The Countach was the first Lamborghini with scissor doors – a feature reserved only for Lamborghinis with 12-cylinder engines. The low, angular, wedge shape was unlike anything else in production. The first Countach, complete with green paint and a periscope rear view mirror, is a star of the museum.

The Diablo, Murcielago, Aventador, Reventon, and Revuelto have topped the Lamborghini model line and carry on the Countach DNA. The museum showed the progression of current and classic cars and offered a look at low-production rarities rarely seen in real life.

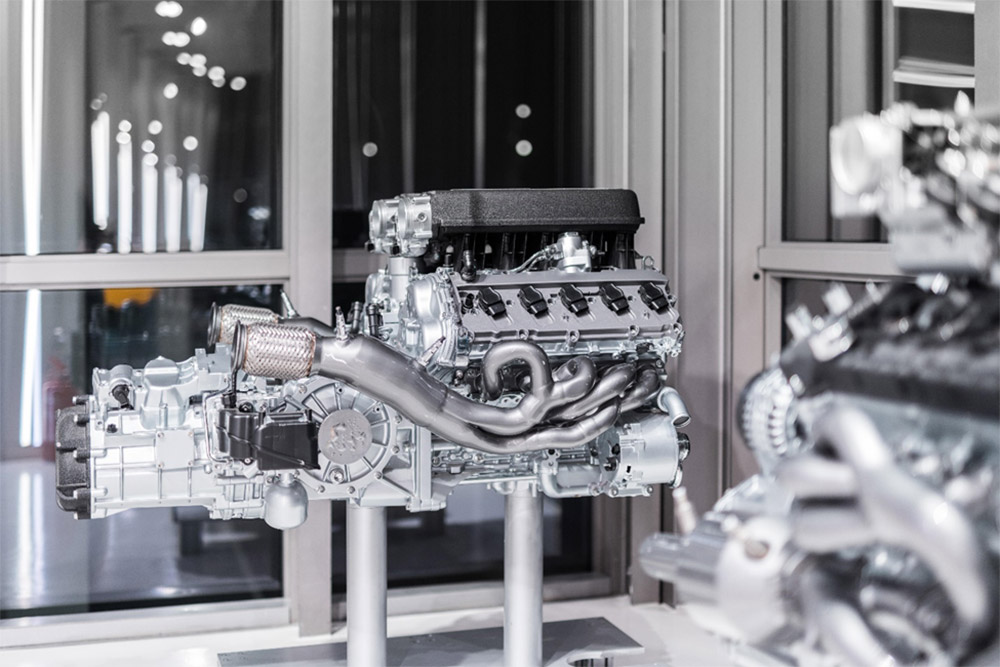

SUV roots at Lamborghini started in 1977 with the Cheetah off-road prototype intended for military use. The well-known LM002 was produced in the late 1980s and early 1990s and was equipped with a V-12 engine taken directly from the Countach. Guests not only see a LM002 but the modern-day Urus off-road offering.

While most cars were clean, shiny, and polished, a highlight of the museum was a green and orange Huracan covered in grime from race duty. The Huracan GT3 on display won the 2019 24 Hours of Daytona. A dirty race-winning car is a pretty car.

The Huracan race car came from the same assembly line that makes Huracan road cars. That being the case, a tour of the assembly lines to see new Lamborghinis taking shape was a welcome part of the visit.

On the short shuttle drive to the factory from the museum, Lamborghinis of all colors waited in parking lots for the next steps of their journey. Some were enveloped in protective wraps to ensure they arrive at their destinations without bumps and bruises. A lucky visitor might even see a glimpse of a prototype or mule of a future model.

Carbon fiber is a big part of Lamborghini production. Three autoclaves bake the material in molds. The factory also uses 3-D printing technology and CNC machines. Laser measuring and virtual reality tools help in the quality control. Italian craftsmanship does not mean only human hands are involved. Robots are engaged for certain tasks, such as applying resin to join carbon fiber parts together.

The tour continued with a visit to the Revuelto assembly line and then the Urus assembly line. In calendar 2023, Lamborghini hit an all-time high of delivering 10,112 cars. A minority were sportscars. Over 6,000 of the vehicles sold were the Urus SUV. Huracans accounted for over 3,000 units. The new top-of-the-line Revuelto is the newest, only having started production in July 2023.

The last stop on the tour was a stop at the Ad Personam studio, Lamborghini’s client customization department. The studio featured a Revuelto and a large assortment of color samples and leather samples and wheels – considerably more than the standard selection dealerships provide. Lamborghini can create colors if not already available. The staff has many stories of customer requests, limited only by the imagination and budget.

A visit to the region would be incomplete without a stop at Lamborghini. With over six decades of history as a foundation and stable ownership as part of the Audi and Volkswagen family, the best may be yet to come. The Speed Journal would like to thank the Lamborghini staff for their hospitality.